Liquid Nitriding

Downloads & Presentation

News

Liquid Nitriding / Salt Bath Nitriding (SBN) / QPQ / Ferritic Nitro-Carburizing (FNC)

Liquid Nitriding is one of the processes of improving surface properties of plain carbon steels, low alloy steels, stainless steels and cast iron. This process improves physical and metallurgical properties like wear resistance, corrosion resistance, frictional properties etc.. Also this process enhances the fatigue strength of the materials.

HEF group is a pioneer of Liquid Nitriding technologies-with over 72 facilities globally operating from 22 countries. HEF manufactures all necessary equipments like salt bath furnaces and required non pollutive chemicals. Their jobbing process is monitored by computer controls for accuracy, repeatability and reliability of processed components.

Process Overview

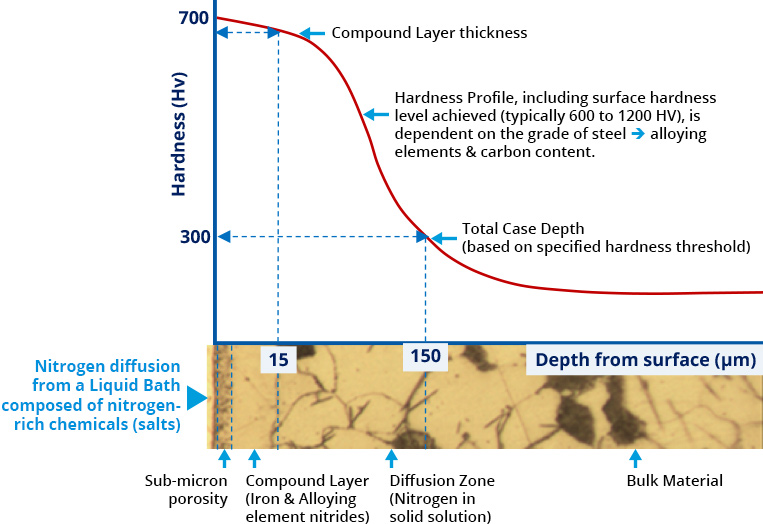

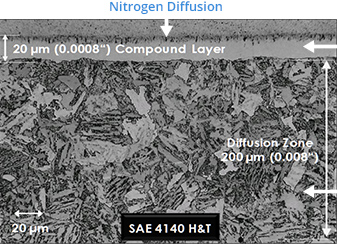

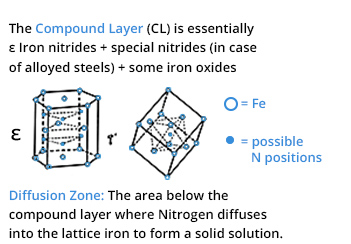

In a liquid nitriding bath, which is maintained between 500 - 630°C (930 - 1165°F), nitrogen-bearing salts produce a controlled and highly uniform release of nitrogen at the surface of the workpiece. Nitrogen diffuses into, and chemically combines with, nitride-forming elements in the metal, producing, through a catalytic reaction, a tough, ductile compound layer with exceptional mechanical properties. This hard compound layer has wear properties that are 200% to 1000% greater than the original material, and greatly enhanced resistance to corrosion, galling and scuffing.

Below the compound zone is another distinctive region, the diffusion zone. This zone results from the progressive diffusion of nitrogen and the formation of a solid solution of nitrogen in the base material. The diffusion zone contributes a critical fourth benefit of salt bath nitriding: substantial enhancement of fatigue strength, typically 20% to 100%.

Below the compound zone is another distinctive region, the diffusion zone. This zone results from the progressive diffusion of nitrogen and the formation of a solid solution of nitrogen in the base material. The diffusion zone contributes a critical fourth benefit of salt bath nitriding: substantial enhancement of fatigue strength, typically 20% to 100%.

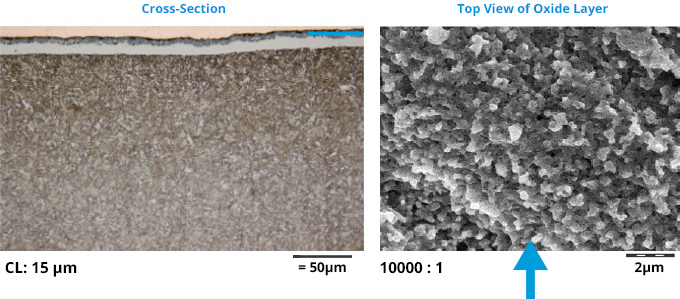

Oxidized Sub-Micron Porosity

Sub-micron size surface porosity:

- Can be tailored for specific applications

- Very useful for impregnating with especially formulated oils & polymers → significant improvement in corrosion protection & run-in characteristics

- Porosity needs to be controlled – excessive amounts can make compound layer friable

Liquid Nitriding Modifies the Surface Metallurgy and Properties of Ferrous Materials